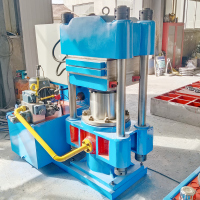

100-Ton Four-Column Plate Vulcanizing Press

Core Technical Parameters

Parameter | Specification |

Nominal Pressure | 100 tons (1000 kN) |

Cylinder Diameter | Φ285 mm |

Plunger Stroke | 300 mm |

Heating Plate Size | 500×500 mm |

Heating Method | Electric heating (zone-controlled, steam/oil heating optional) |

Temperature Range | Room temp. ~200°C (PID precision control) |

Working Layers | Single/Double (optional) |

Control System | Siemens PLC + Touchscreen |

Key Advantages:

High-Precision Control

Siemens PLC + pressure sensor closed-loop control, pressure deviation ≤±1%, ensuring superior pressure stability.

Independent PID temperature control for each heating zone, eliminating uneven vulcanization.

Exceptional Durability

Four-column guided structure resists deflection and maintains long-term stability.

High Automation Level

Pre-set multiple process recipes for quick product changeovers without manual adjustments.

Wide Applicability

Materials: Rubber, silicone, PVC, EVA, composites.

Products: Seals, shock pads, shoe soles, medical silicone parts, automotive components.

Value-Added Services (Boosting Conversion)

✔ Free Technical Consultation: Optimize process parameters for your product.

✔ 24/7 After-Sales Support: Remote debugging or on-site engineer assistance.

✔ Customization Options: Upgrade to servo hydraulic system or robotic auto-ejection.

Phone: 18561609661

Email: qdjiaxinrun@163.com

Address: Wangtai Town Industrial Park, Huangdao District, Qingdao City, Shandong Province

Scan to add official WeChat

Technologyreal-time info

在线客服

在线客服

在线客服

在线客服