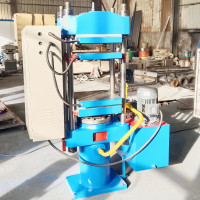

50 ton hydraulic vulcanizer

50-Ton Four-Column Double-Layer Manual Vulcanizing Machine Product Introduction

Product Overview:

This machine is a manually controlled vulcanizing press featuring a four-column guided structure and a double-layer worktable design. It is specifically designed for compression molding and vulcanization of rubber products (such as seals, shoe soles, tire repairs, etc.). The manual hydraulic control ensures easy operation, while the double-layer design enhances production efficiency, making it ideal for small and medium-sized rubber product manufacturers.

Product Features:

High-Strength Structure: Four-column guidance ensures precise mold clamping, and the double-layer design enables simultaneous vulcanization, doubling efficiency.

Manual Hydraulic Control: Simple operation, low maintenance costs, suitable for environments without electricity.

Uniform Heating: High-quality heating plates paired with a temperature controller ensure a temperature deviation of ≤±3°C.

Safe and Reliable: Mechanical limit + hydraulic overload protection + anti-pinch hand design.

Versatile Application: Customizable mold slots to adapt to various rubber product requirements.

Applications:

Rubber seals, gaskets, O-rings

Shoe soles, rubber tire repairs

Industrial rubber component molding

50-Ton Vulcanizing Machine Technical Specifications:

Parameter | Value |

Nominal Clamping Force | 0.50 MN (500 kN) |

Heating Plate Size | 400 mm × 400 mm |

Plate Spacing | 150 mm |

Pressure per Unit Area | 3.2 MPa |

Number of Working Layers | 2 layers |

Plunger Diameter | 200 mm |

Number of Cylinders | 1 |

Plunger Stroke | 300 mm |

Working Hydraulic Pressure | 16 MPa |

Heating Method | Electric heating (standard) or steam heating |

Heating Temperature | Room temperature ~ 200°C (adjustable) |

Motor Power | 2.2 kW |

Control Method | Manual hydraulic valve control |

Electrical Components Brand | CHINT |

Structure | Four-column guided, double-layer structure |

Phone: 18561609661

Email: qdjiaxinrun@163.com

Address: Wangtai Town Industrial Park, Huangdao District, Qingdao City, Shandong Province

Scan to add official WeChat

Technologyreal-time info

在线客服

在线客服

在线客服

在线客服