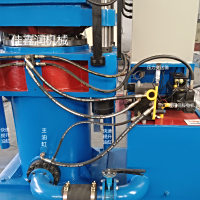

400T Servo Vulcanizing Machine

Features of the 400-Ton Four-Column Servo Hydraulic Vulcanizing Machine

Efficient Mold Clamping System:400-ton mold clamping force meets the demands of high-strength vulcanization processes, ensuring product molding quality.

Four-column structure design provides stable support and uniform pressure distribution, suitable for high-precision vulcanization operations.

Multi-Layer Hot Plate Design:4-layer working space with a hot plate spacing of ≥200 mm per layer, suitable for multi-layer vulcanization needs, significantly improving production efficiency.

Hot plate size ≥800×800 mm, suitable for vulcanizing large-sized products, with a wide range of applications.

Precise Temperature Control System:

Electric heating method with precise temperature control, temperature deviation ≤±3℃, ensuring uniform temperature during vulcanization.

Maximum heating temperature up to 250℃, meeting the vulcanization temperature requirements of various materials.

High-Performance Hydraulic System:

The servo hydraulic system provides powerful power support and precise control with high precision, efficiency, and stability.

Main cylinder stroke ≥800 mm, suitable for large-sized product production.

Excellent pressure-holding performance ensures stable pressure during vulcanization.

Intelligent Control System:

PLC automatic control supports fully automatic operation and manual control functions, offering flexible and convenient operation.

Automated action procedures, from jog start to automatic mold opening, require no manual intervention, improving production efficiency.

Wide Applicability:Suitable for rubber products, composite materials, seals, and other production processes requiring high-temperature and high-pressure molding.

Technical Parameters of 400-Ton Four-Column Servo Hydraulic Vulcanizing Machine

Parameter Name | Technical Specification |

Nominal Mold Clamping Force | ≥400 tons |

Type | Four-column |

Structure | Single unit |

Plate Pressure | 3.125 MPa |

Hot Plate Size | ≥800×800 mm (5 plates) |

Hot Plate Spacing | ≥200 mm (per layer) |

Working Layers | 4 layers |

Heating Method | Electric heating |

Temperature Deviation | ≤±3℃ |

Maximum Heating Temperature | Room temperature - 250℃ |

Main Cylinder Stroke | ≥800 mm |

Main Cylinder Diameter × Quantity | ≥500 mm × 1 set |

Operating Environment Temperature | -10℃ ~ 45℃ |

Power Supply | 380V 50Hz 3PH |

Pressure-Holding Performance | Pressure drop ≤10% within 1 hour |

Control Method | PLC automatic control |

Action Procedure | Jog start - Automatic rapid rise - Mold closing and pressure application - Automatic exhaust - Vulcanization timing (automatic pressure compensation) - Alarm at completion - Automatic mold opening |

This translation provides a comprehensive overview of the 400-Ton Four-Column Servo Hydraulic Vulcanizing Machine, including its features, technical parameters, and applications, suitable for international communication and marketing purposes.

Phone: 18561609661

Email: qdjiaxinrun@163.com

Address: Wangtai Town Industrial Park, Huangdao District, Qingdao City, Shandong Province

Scan to add official WeChat

Technologyreal-time info

在线客服

在线客服

在线客服

在线客服