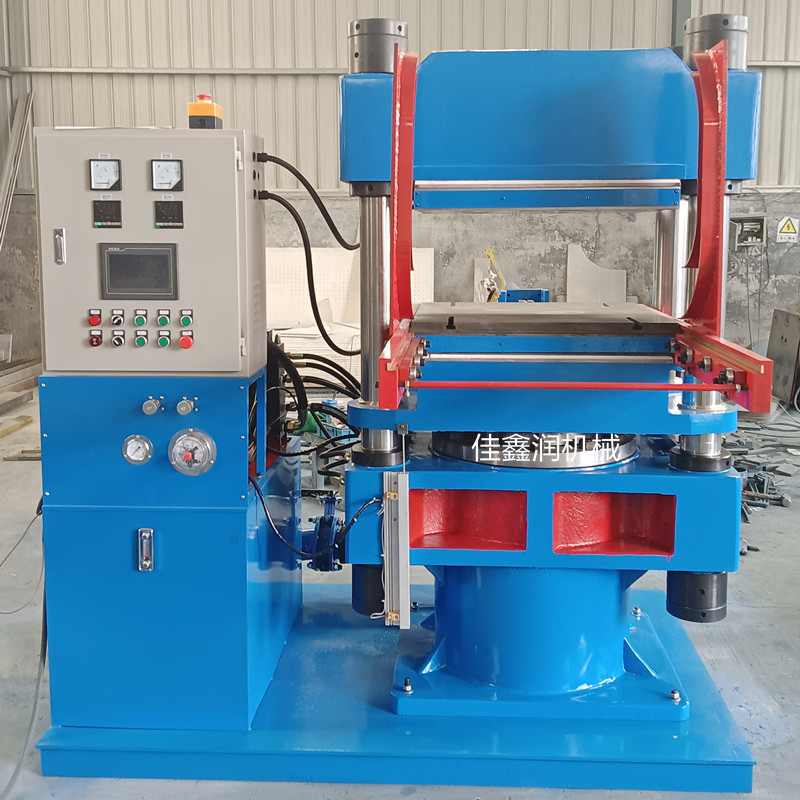

250-ton Plate Vulcanizing Machine

250-ton Track Turning Plate Vulcanizing Machine

Product Overview:

The 250-ton track turning plate vulcanizing machine is a heavy-duty equipment used for vulcanizing various rubber molded products. It can also be used for press molding of thermosetting plastics, resins, bakelite, and other materials. It is widely applied in the production of rubber products such as tires, conveyor belts, hoses, and seals. The turning plate mechanism enables the flipping and opening/closing of molds, facilitating easy loading and unloading of materials.

Product Features:High Clamping Force: The 250-ton clamping force meets the vulcanization requirements of large rubber products.

Rapid Mold Opening/Closing: High production efficiency with slow-speed locking to protect molds.

New Sealing Components: Reliable sealing with extended service life.

Turning Plate Structure: Convenient loading and unloading, improving production efficiency.

High Automation: Equipped with a PLC control system and touch screen display for automated operation.

Safe and Reliable: Includes safety protection devices to ensure operator safety.

Technical Parameters:

Parameter | Value |

Nominal Pressure (Clamping Force) | 250 tons (2500 kN) |

Heating Method | Electric Heating |

Heating Power | 21.6 kW |

Temperature Range | Room Temperature ~ 200°C |

Pressure Range | 0~20 MPa (Adjustable) |

Platen Size | 800mm × 800mm (Customizable) |

Number of Layers | Single Layer |

Turning Angle | 90°~180° |

Platen Spacing | 300mm (Based on Mold Height) |

Table Height | 800mm |

Control Method | PLC Automatic Control |

Temperature Control | PID Precise Temperature Control |

Pressure Control | Hydraulic System, Adjustable Pressure |

Vulcanization Time | 0~999 Seconds (Adjustable) |

Automation Functions | Automatic Mold Opening/Closing, Automatic Turning, Automatic Exhaust |

Cylinder Diameter | 450mm |

Overload Protection | Hydraulic System Overload Protection |

Over-Temperature Protection | Automatic Shutdown for Over-Temperature |

Emergency Stop | Emergency Stop Button |

Applicable Materials | Rubber, Silicone, Plastics, etc. |

Vulcanization Cycle | Typically a few minutes to tens of minutes, depending on process requirements |

Phone: 18561609661

Email: qdjiaxinrun@163.com

Address: Wangtai Town Industrial Park, Huangdao District, Qingdao City, Shandong Province

Scan to add official WeChat

Technologyreal-time info

在线客服

在线客服

在线客服

在线客服